Products

Autoclave ACBV

ACBV series

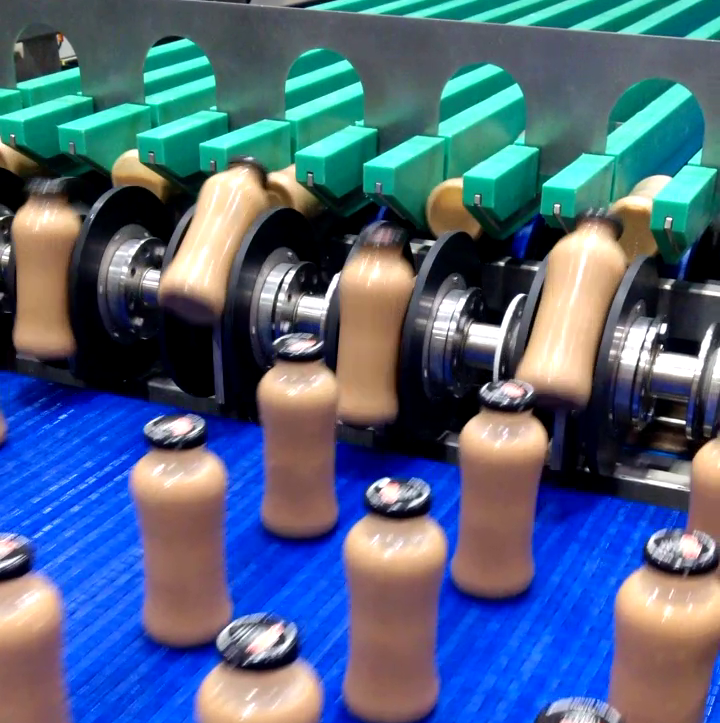

The rotary continuous retort ACBV is specially designed for sterilisation of products packed in glass bottles and jars (Milk, beverages, soupes, vegetables, …)

The continuous agitation of the product during the heating and cooling process prevents from any burnt product. The pre-heating device used for energy recycling is also necessary to avoid the thermical stress of the glass packagings.

This continuous sterilizer is specially designed for medium to large productions and can run different sizes and shapes of packaging within the same machine.

Special packaging such as jars or bottles with twist off caps can be processed with the addition of the ovepressure module.

Cooling is achieved in 2 phases:

1- water immersion pressure cooling;

2- water immersion at atmospheric pressure;

- FULL Rotation to increase Heat Penetration and to reduce Cooking time

- Flexibility on product sizes,

- Limitation of heat stress thanks to pre-heater and ATM cooler,

- Can be equipped with Over Pressure when using twist off caps,

- Pre-heater is also an energy recycler

- Energy efficient (low energy consumption)

- Fully automated (low labour)

- FLEXIBILITY : one machine can process different sizes and type of packaging

- Throughput up to 30 000 bottles per hour